Before we start making a cat5e/Cat6 patch cable, need to cut a standard length of Cat5e/Cat6 cable. After cutting the length you should make sure to measurement. Nothing is worse than the patch cable you just built being an inch too short for your application. After cutting the wanted length we will start building our patch cable by shedding back about 1 inch of the jacket

After striping makes sure that the depth of your stripper is set deep enough to cut the jacket but not so deep that it nicks the conductors of the cable. If you do groove the conductors while shedding the cable, the cable may work fine at first, but after some time may be the conductors will break.

Now we have the shielded jacket we'll want to separate and bend the pairs. We'll start by pushing the first pair and the last pair to their other sides (Orange to the left side and Brown to the right side). Untwist these pairs of cat5e/cat6 plenum cable any further than you've shielded the jacket. Now we'll split the green pair. Pull the white/green conductors to the opposite sides. And the blue pair in the middle. Untwist the blue and white/blue conductor in against sides.

Note: Usually, it would be unmentionable to untwist the Cat5e/Cat6 pairs, not including when building patch cables. It would be almost unmanageable to pull out the conductors into the correct connector locations deprived of untwisting.

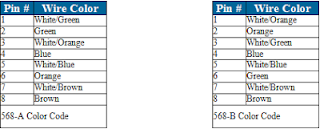

Now that we've parted and straightened the pairs we want to place the conductors in the suitable order according to which cabling standard you are spending. For this case, we will be cabling via the 568-B normal (most common in patch cables). Consult the pin-out for the correct color codes. After you have the wires settled, place them strongly together as shown in the picture. Once this is done, confirm that the cables are still in the accurate order and continue to next step.

Now we need to slim the electrodes down to fit into the RJ45 connector. While adornment, make sure you make a nice clean cut at a 90-grade angle around 1/2 of an inch from the end of the cover. If you fail to make a cut, some of the electrodes may not reach the connector associates. If you cut the electrodes too small, again they will not make communication. If you leave the electrodes too long, when crinkling the connector, the covering will not be spellbound leaving the rinsing on the electrodes. This is not a good condition! For proper garnish, hold the wires securely just at the end of the cover as shown in the picture. Be assured to keep the electrodes in the right order.

Our Cat5e patch cable is almost done. Although still holding the cable definitely, we now want to place the rods into their right location in the RJ45 Cat5e/cat6 Linked Connector. Hold the RJ45 linked plug with the links facing up and prudently pullout the conductors in their correct locations. Apply a modest quantity of force in order to correctly seat the cables against the links in the connector. When the cables have been correctly put into the RJ45 linked connector, detect the tip. As shown in the picture to the left you must be able to see the end of each electrode, representative that the rods were fully injected. Also, take the remainder of the colors. All white conductors should be on the top and all the colored conductors on the bottom.

Many customers have testified that they find Cat5e/cat6 Connectors with load bars much relaxed to use during the close process. The load bar is used to bring into line the conductors into the proper place and hold them in place during addition.

If you are structuring a straight through Cat5e/cat6 patch cable, terminate the opposed end by recapping this process from the first step. If this will be a cat 5/ cat6 cusp cables, return the first step and continue; however, terminate the second end of the cable using the cabling system that you didn’t use for the first end. Terminating one finish with 568-B and the second one with 568-A makes a crossover wire. If it is a straight through wire you are making, simply use the same cabling arrangement for both ends.

Note: If the cat6/cat5e plenum cable does not test positive for continuity cut the connector off and start over, or buy one of our pre-made or custom length patch cords.

For More Information Visit Our Website

0 comments:

Post a Comment